3d Printing IRL

So, I wanted to share my reflections on my first month with a 3d printer. I recently wrote about our experiences choosing, ordering, and setting up a 3d printer here at Spring Grove Middle School. I'd like to share some thoughts with you for the good of the cause on what having a 3d printer is like "in real life" (IRL). If you're considering adding a 3d Printer, these are some ideas, experiences, thoughts, and issues you might want to consider.

Honestly, we ordered the Cube 3 with the thought that paying a little extra for filament cartridges and giving up the ability to use open-source software, we were being rewarded with an Apple-like simplified end-user experience that was deigned to "just work". Thank God for the following videos, which helped me tear down and fix numerous problems that came up with our cartridges over the last month:

Plan on it.

Unfortunately, 3d Printing is still a new technology with a lot of hype surrounding it. Chances are, at some point, you've seen something like the video below that has you feeling all squishy about 3d Printing:

A lot of this information is accurate even though it is grossly over-simplified. The big issue with adding a 3d Printer to the mix of any classroom is the need for a plan.

So, I'm pretty big on Project Based Learning, Problem Based Learning, and student choice. I can get a way with it too, because I don't teach a tested content area. In my class, a student simply needs to display technology fluency. Whether she does this by developing games, designing a fashion brand, or drafting a LEED certified home makes little difference to me. My first key to success, therefore, is to...

Here are the apps that we use in my class.

Tinkercad is a browser-based 3D design and modeling tool. It has the most gentle learning curve, and it's built in tutorials are very intuitive for students. It doesn't require an install, so you don't have to bug your IT department. It renders very basic models, but they're made for 3d printing. In other words, solid parts of your parts are automatically rendered with an internal lattice to provide strength while using less filament.

Sketchup Make has a gradual learning curve but is still very powerful, allowing students to build very detailed parts with very accurate measurements. Unfortunately, the company wants you to fork over 695.00 USD for Sketchup Pro if you want to 3d Print natively. Luckily, there are plugins. I have had a lot of students be very successful with printing from Sketchup Make with the plugins. Unfortunately the model is not constructed as efficiently and you have to manipulate its structure slightly in whatever slicing application comes with your printer.

From what I understand, Solidworks is the best program for building quality 3d parts. I just can't figure out how to use it efficiently. I've done the tutorials, but I don't get the logic of the application enough at this point to create something from scratch. I have students that figure this program out, but most of them don't try. We pay for this thing. Yeah, this is the one with the steep learning curve. Good luck. The tutorials on the Solidworks web site were definitely made by developers. They are convoluted, difficult to follow, and, worst of all for may students, are vey uninteresting. No eighth grader gets excited about making this, whatever it is... If anyone has a good tutorial series (that's free... no Lynda paywall junk) for this, please post it in comments.

Parting

If I have any other suggestion, it would be to find a community of folks to help you. It will be a lot easier if you can talk to others who have done / are doing this. Also, watch as much user-generated content on "making" and 3d printing that you can find on YouTube. Geek out on it. Then pick a low-end printer and figure out what the issues are before expanding your operation.

Good luck.

DFTBA

Know you will have issues

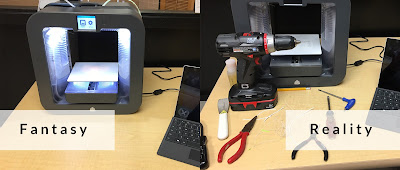

3d Printing is not ready for prime time. No matter what mainstream manufacturers would want you to believe, 3d printing is for makers and enthusiasts. It is not a seamless, out-of-the-box plug-and-play casual consumer experience. You can buy the "Fisher Price" of 3d printers and still end up tearing stuff apart and fixing it on a regular basis. Have tools, and be prepared to use them. |

| Unfortunately, the fantasy & the reality of owning a plug-and-play 3d printer didn't line up. |

Honestly, we ordered the Cube 3 with the thought that paying a little extra for filament cartridges and giving up the ability to use open-source software, we were being rewarded with an Apple-like simplified end-user experience that was deigned to "just work". Thank God for the following videos, which helped me tear down and fix numerous problems that came up with our cartridges over the last month:

- 3D Systems Cube 3 PLA Cartridge Clog (Cartridge Jam) by Kn3rdG@sm

- How To Fix A Jammed 3D Systems Cubify Cube 3 3D Printer Cartridge by Kn3rdG@sm

- Ekocycle Cube Clogged Head Repair by Transformersfang138

Plan on it.

Plan the Work and Work the Plan

So, 3d Printing is cool. I'm not going to lie. It's a guaranteed way to capture students' attention. It is definitely the "best" way I have found to get students interested in technical drawing and drawing in 3d.

Unfortunately, 3d Printing is still a new technology with a lot of hype surrounding it. Chances are, at some point, you've seen something like the video below that has you feeling all squishy about 3d Printing:

A lot of this information is accurate even though it is grossly over-simplified. The big issue with adding a 3d Printer to the mix of any classroom is the need for a plan.

- What are students going to do with this?

- What constitutes an acceptable and unacceptable use of the printer?

- How do we avoid putting the school in debt buying filament?

Out-sourcing, student choice, and PBL

|

| Students should first think of a product that fills a need or has a niche. |

So, I'm pretty big on Project Based Learning, Problem Based Learning, and student choice. I can get a way with it too, because I don't teach a tested content area. In my class, a student simply needs to display technology fluency. Whether she does this by developing games, designing a fashion brand, or drafting a LEED certified home makes little difference to me. My first key to success, therefore, is to...

Make sure that 3d Printing is a choice.The next step is to make sure that students know what they are choosing. If a student is 3d Printing in my class, it isn't a stand-alone "3d printing project". It is most likely in the context of something like a Product Design, Game Design, or Video project. The printing, therefore, exists to solve a problem, prototype a product, or create something entirely unique. This prevents students from trying to print key chains for their friends, little rectangles with their name on it, and other random items connected to nothing.This brings me to my next key to success:

Put the context before the printer.Finally, it is important to understand that not every student is good at or will even like every part of a project. I don't encourage "group projects" in my room, per se, because they're rarely successful and everything is really a group project. My students freely outsource the work they need done. If a budding videographer needs a new shooting rig, she can ask another student to make and print it for her. If an inspiring inventor needs a logo and package design for the cool prototype he just printed, he can have a student who is doing a graphic design project make that for him. In the end, everyone has cool stuff to add to their portfolio of awesomeness, and no one is bogged down in miserable monotony. This goes back to making sure that 3d Printing is a choice.

Reward Awesomeness

When a student does something awesome, invite the Principal over. Post it to Tumblr. Tweet it. Make sure that other students are seeing the possibilities. Make sure that the community is seeing the possibilities.

The Software Landscape

Ugh. Okay, so the software landscape is a bit challenging. Many companies have their own proprietary design apps, which should work seamlessly with their printer, but most are at least $40.00 + per license.Here are the apps that we use in my class.

Tinkercad

tinkercad.comTinkercad is a browser-based 3D design and modeling tool. It has the most gentle learning curve, and it's built in tutorials are very intuitive for students. It doesn't require an install, so you don't have to bug your IT department. It renders very basic models, but they're made for 3d printing. In other words, solid parts of your parts are automatically rendered with an internal lattice to provide strength while using less filament.

Sketchup Make

sketchup.com/products/sketchup-makeSketchup Make has a gradual learning curve but is still very powerful, allowing students to build very detailed parts with very accurate measurements. Unfortunately, the company wants you to fork over 695.00 USD for Sketchup Pro if you want to 3d Print natively. Luckily, there are plugins. I have had a lot of students be very successful with printing from Sketchup Make with the plugins. Unfortunately the model is not constructed as efficiently and you have to manipulate its structure slightly in whatever slicing application comes with your printer.

Solidworks

solidworks.comFrom what I understand, Solidworks is the best program for building quality 3d parts. I just can't figure out how to use it efficiently. I've done the tutorials, but I don't get the logic of the application enough at this point to create something from scratch. I have students that figure this program out, but most of them don't try. We pay for this thing. Yeah, this is the one with the steep learning curve. Good luck. The tutorials on the Solidworks web site were definitely made by developers. They are convoluted, difficult to follow, and, worst of all for may students, are vey uninteresting. No eighth grader gets excited about making this, whatever it is... If anyone has a good tutorial series (that's free... no Lynda paywall junk) for this, please post it in comments.

Parting Shots... er Thoughts

If I have any other suggestion, it would be to find a community of folks to help you. It will be a lot easier if you can talk to others who have done / are doing this. Also, watch as much user-generated content on "making" and 3d printing that you can find on YouTube. Geek out on it. Then pick a low-end printer and figure out what the issues are before expanding your operation.

Good luck.

DFTBA

Comments

Post a Comment